Advantages

The executive standard is EN124, which stipulates various technical requirements and testing methods for manhole covers. In terms of anti-settlement, ductile iron manhole covers usually adopt special designs, such as adding support structures or adopting anti-liquid level drop technology, which can effectively prevent the manhole covers from sinking or dislocation due to foundation settlement. This anti-settling measure helps to ensure safe passage of roads and pedestrian areas, and reduces accidents and damages caused by the settlement of manhole covers. It is recommended that when selecting and installing nodular cast iron manhole covers, it is necessary to ensure that they meet the requirements of the load-bearing class A15 and the implementation standard EN124, and select appropriate anti-settlement measures according to the actual situation to ensure the stability and service life of the manhole cover.

Our ductile iron manhole covers are built to last. Its durable construction and corrosion-resistant properties make it suitable for use in a variety of environments, including areas prone to severe weather conditions. The strong ductile iron material ensures our covers will stand the test of time and heavy use, reducing the need for frequent replacements.

Feature

★ Ductile iron

★ EN124 A15

★ High strength

★ Corrosion resistance

★ Noiseless

★ Customizable

A15 Specifications

|

Description |

Loading Class |

Material |

||

|

External size |

Clear Openging |

Depth |

||

|

200x200 |

180x180 |

30 |

A15 |

Ductile iron |

|

300x300 |

270x270 |

30 |

A15 |

Ductile iron |

|

400x400 |

370x370 |

30 |

A15 |

Ductile iron |

|

500x500 |

450x450 |

40 |

A15 |

Ductile iron |

|

600x600 |

550x550 |

40 |

A15 |

Ductile iron |

|

φ300 |

φ260 |

30 |

A15 |

Ductile iron |

|

φ500 |

φ450 |

40 |

A15 |

Ductile iron |

|

φ600 |

φ550 |

50 |

A15 |

Ductile iron |

| Customized according to customer requirements | ||||

Product Details

-

Anti-settling square quiet EN124 E600 ductile i...

-

Anti-settling round quiet EN124 D400 ductile ir...

-

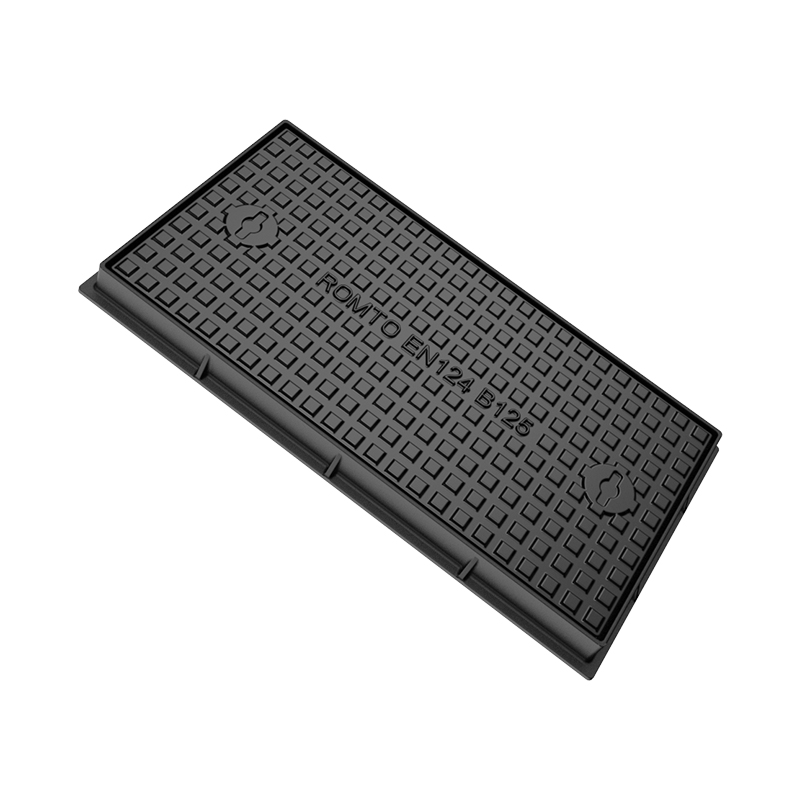

Anti-settling round quiet EN124 B125 ductile ir...

-

Anti-settling square quiet EN124 C250 ductile i...

-

Anti-settling square quiet EN124 B125 ductile i...

-

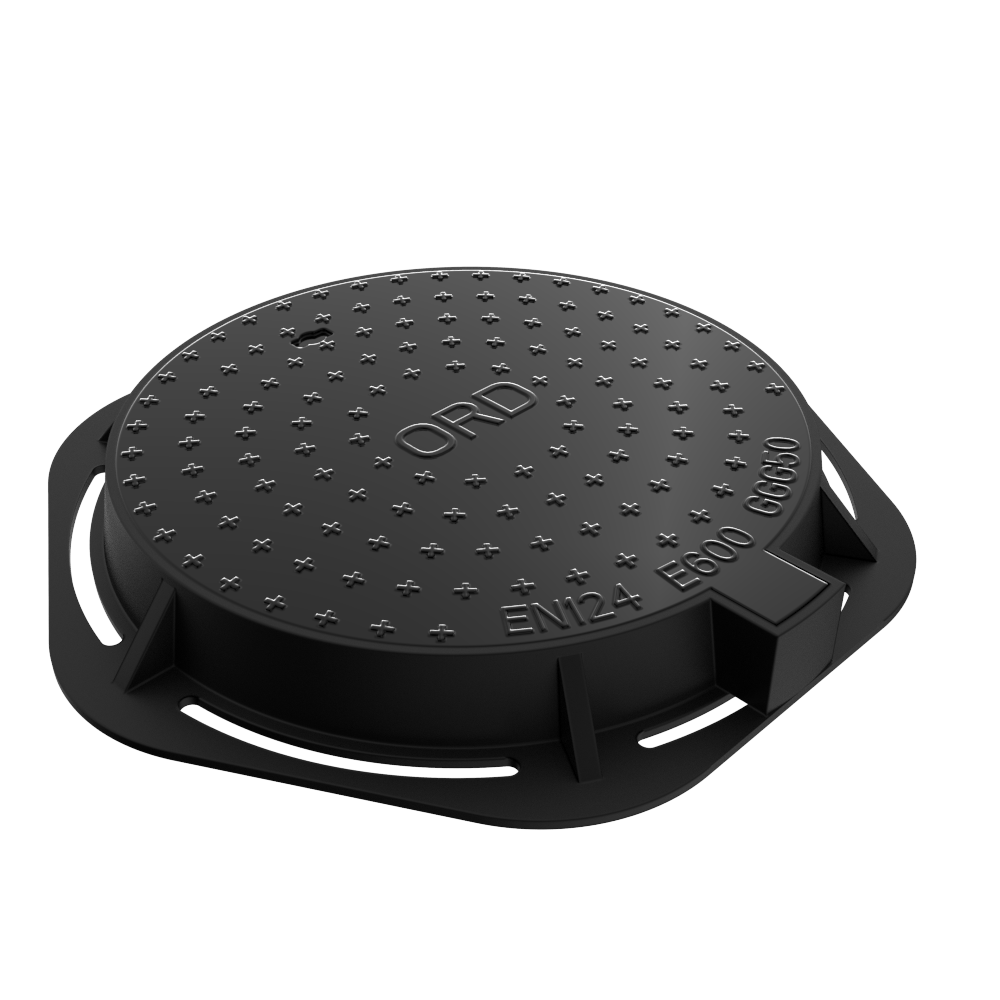

Anti-settling round quiet EN124 E600 ductile ir...